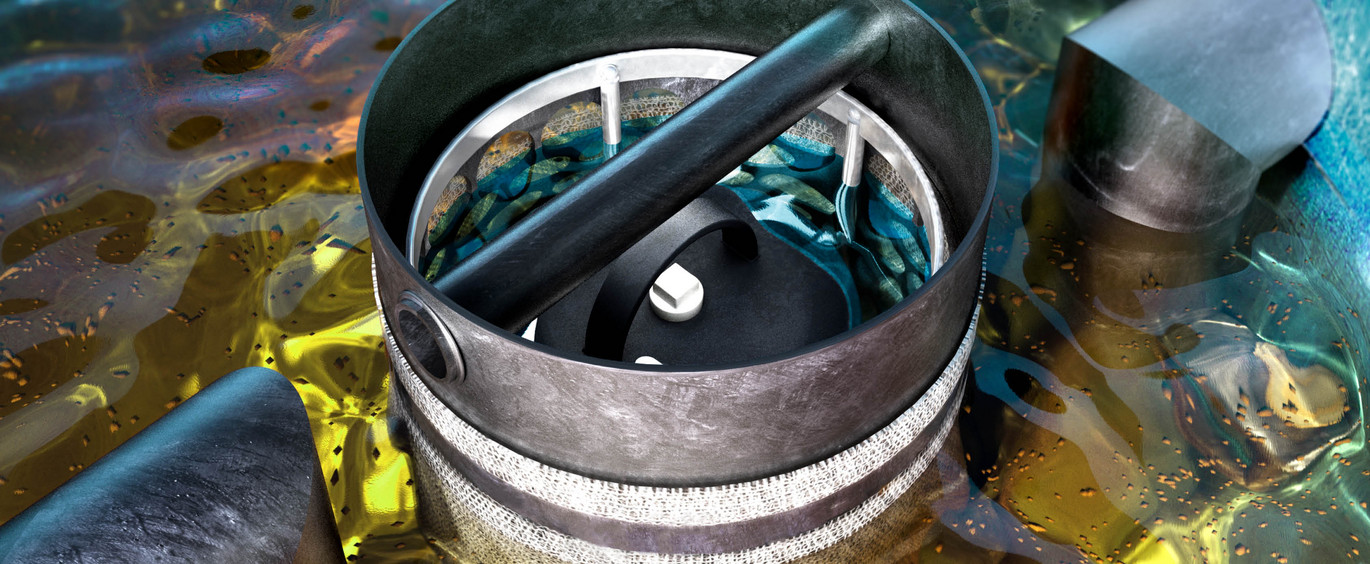

ACO Oleopators are gravity or filter separation based pieces of equipment that separate light liquids, such as mineral oils, fuels and hydrocarbons, and suspended solids from polluted water before it is discharged into the sewer system. Light liquids (oil) have a specific density less than 1 (water). Solids (sludge) have a specific density greater than 1.

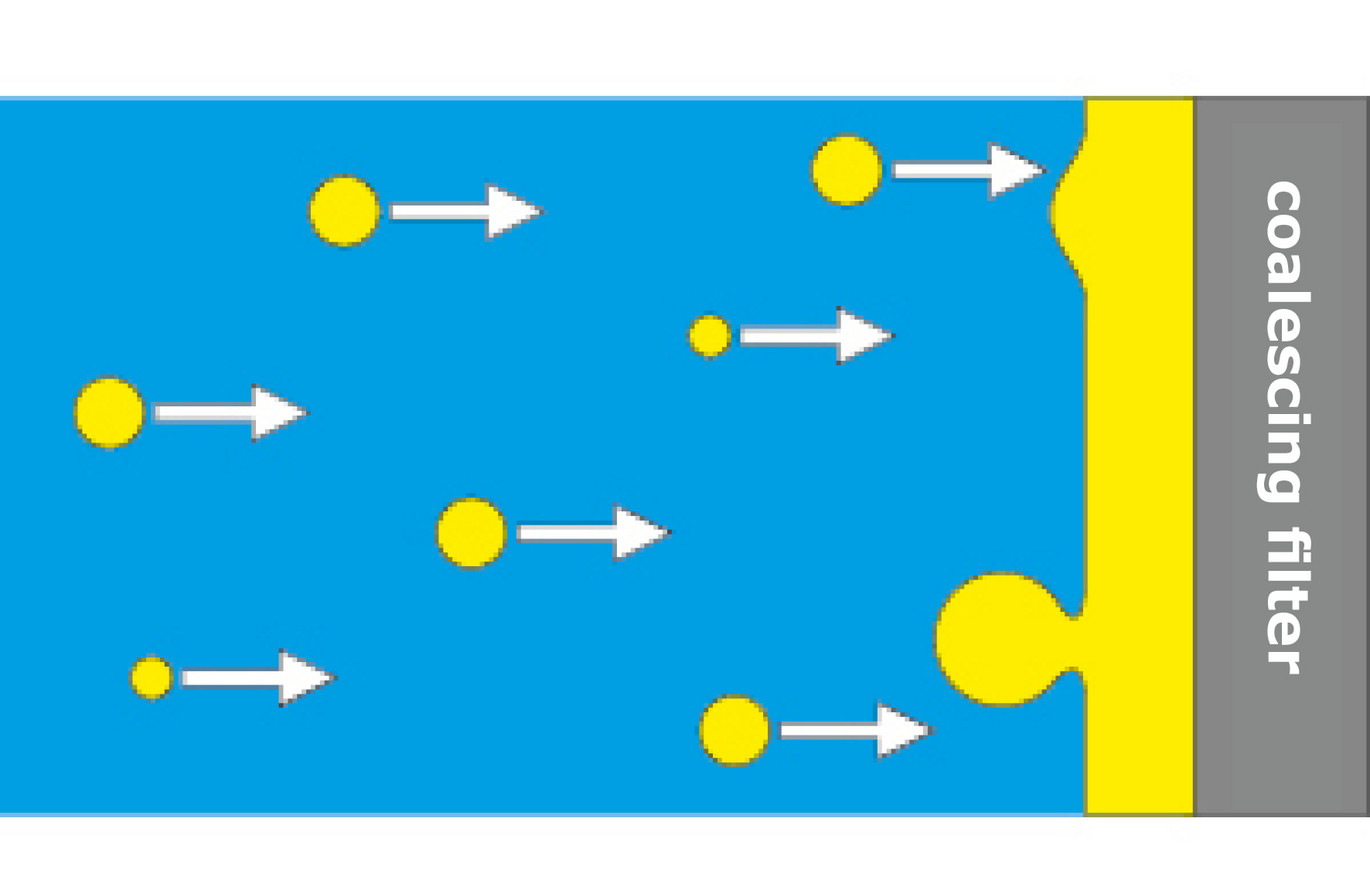

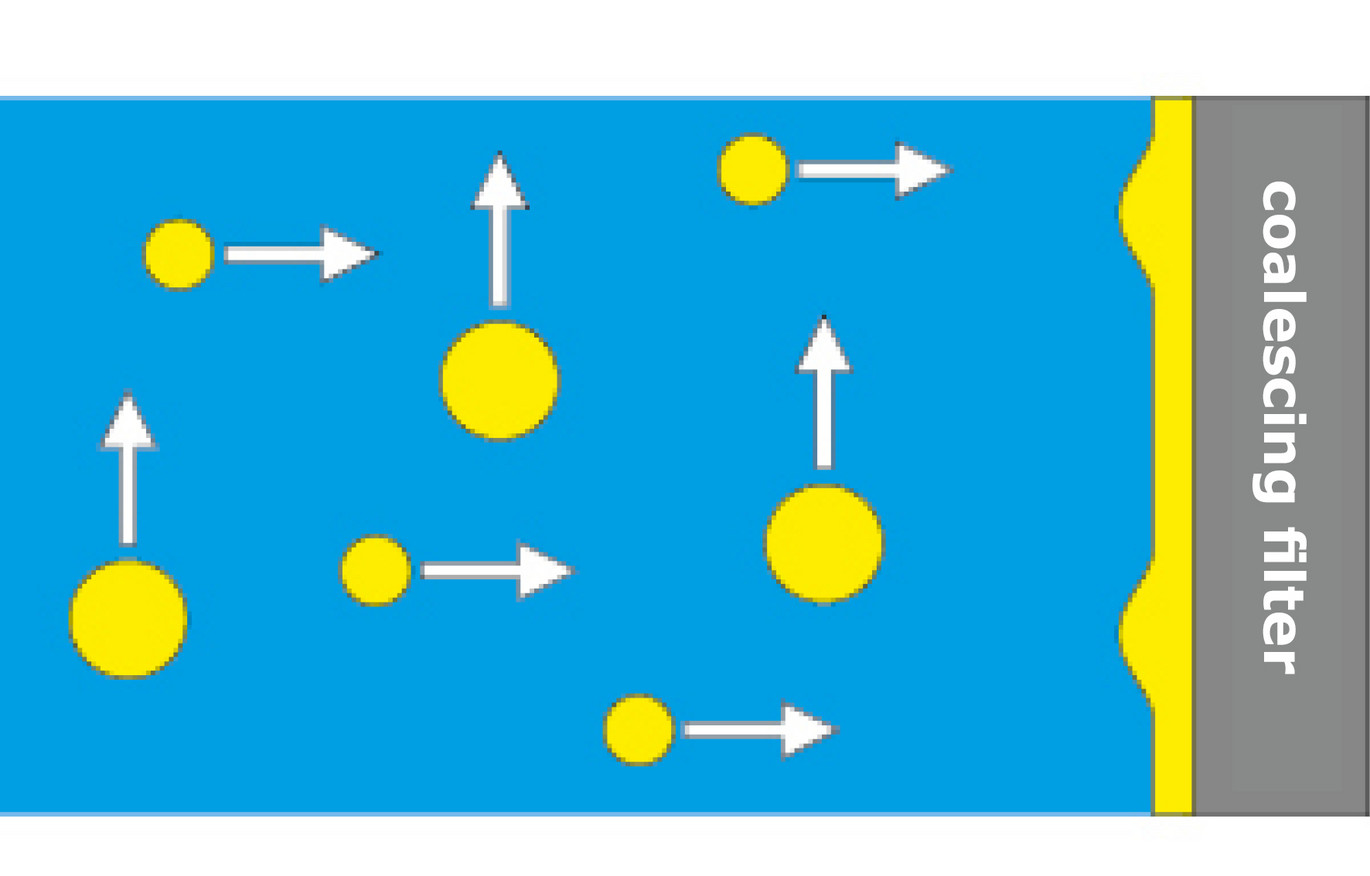

The process by which two or more droplets, bubbles or particles, merge during contact to form a single droplet, bubble or particle.

The small oil droplets which cannot be separa ted from the water on the basis of their diffe rence in density to the water, hit and stick to the lipophilic coalescence unit.

Application:

- Petrol Stations

- Parking Areas

- Carriageways

- Cleaning Sites and Car-wash Plants

- Workshops

- Vehicle Recycling

- Heliports

- Transformer Substations

- Elevator Shafts

Can ACO Oil Separators be used in commercial kitchens?

No. The term ‘oil’ refers to hydrocarbon derivatives. Grease, F.O.G., from the food industry and fatsfrom animal and vegetable sources behave differently than ‘oil’, therefore, kitchen based grease

requires an ACO grease separator.