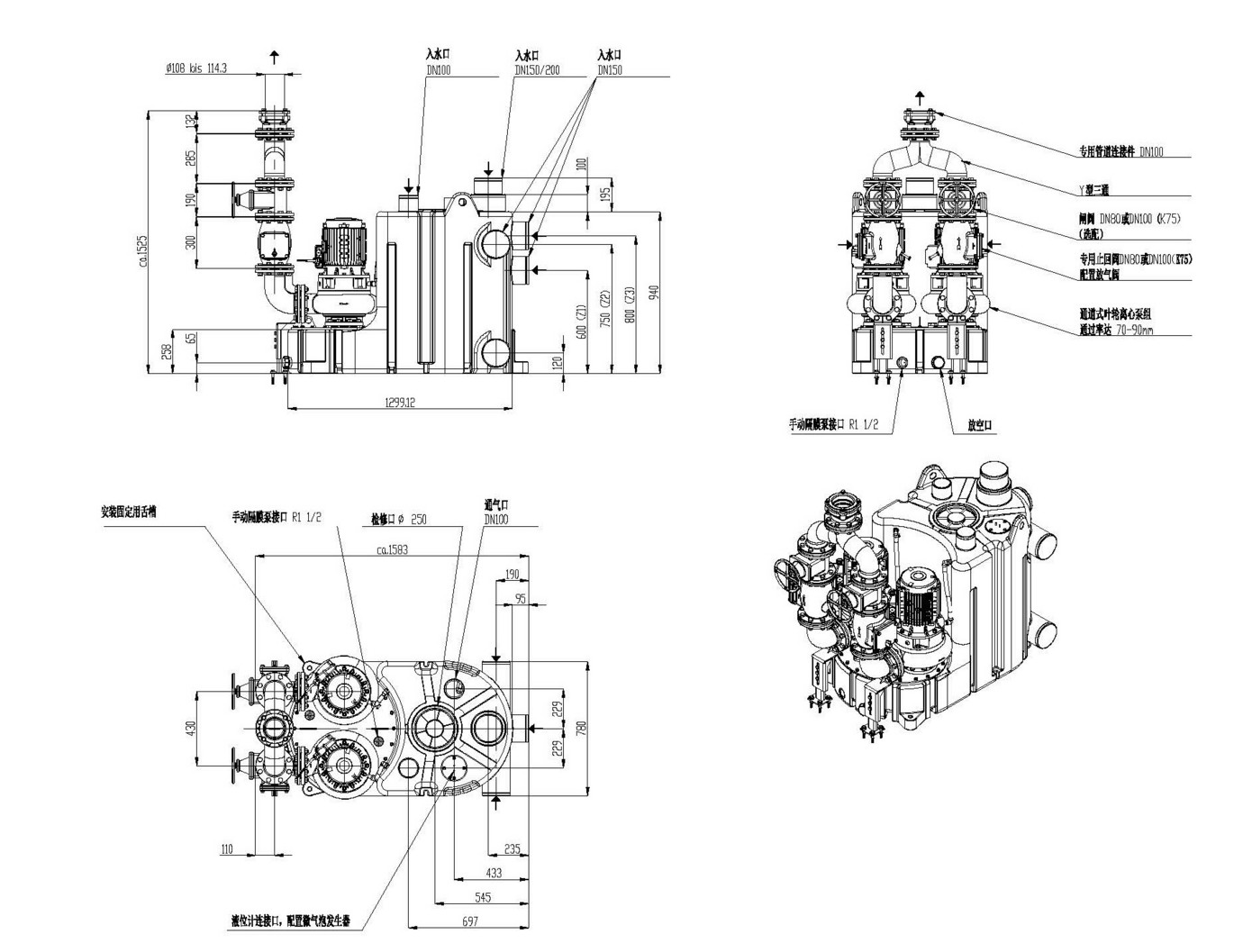

Polyethylene tank:

- Tank total volume 500L

- Scour outlet R 1"

- Service opening for simple maintenance, diameter: 340 mm

- Fixing kit for attachment against floating

- Connector for hand membrane pump DN 50

Inlet connection:

- 4 horizontal intake sockets DN 150

- 1 vertical inlet sockets DN 150

- 1 ventilation socket DN 100

Connection pressure line:

- With 2 special backflow stops with venting device

- With Y-branch

- With special mounting adapter DN 100 for connection of 108 – 114.3 mm pipe external diameter pressure line

- Selectable special valves for maintenance

Level switching:

- Pneumatic level switching

- 10 m control lines

- Optionally with air bubble injection for increased operational security when installing downstream of grease separators (accessory)