In restaurants, commercial kitchens and meat processing plants, grease in wastewater can accumulate. This kind of greasy wastewater is quite different from domestic wastewater, causing risks to pipelines and sanitary drainage objects. Greases and oils deposit on the walls of the pipes together with other wastewater constituents and can lead to corrosion, blockages and odour nuisance. For these reasons, the use of grease separators is mandatory in industrial and commercial environments where grease-polluted wastewater is produced.

Underground Installation Grease Separator LipuMax

ACO Passavant LipuMax-P grease separator made of polyethylene for below ground installation.

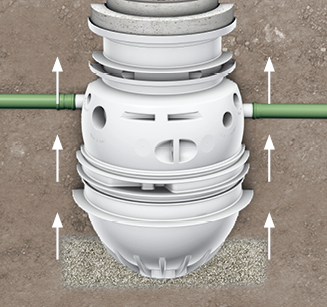

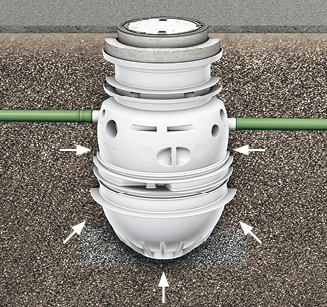

Structural stability

Product stability guaranteed for 50 years

- Certified statics have been calculated for the tank system

- The tank system supplies structural stability for 50 years

Design advantages

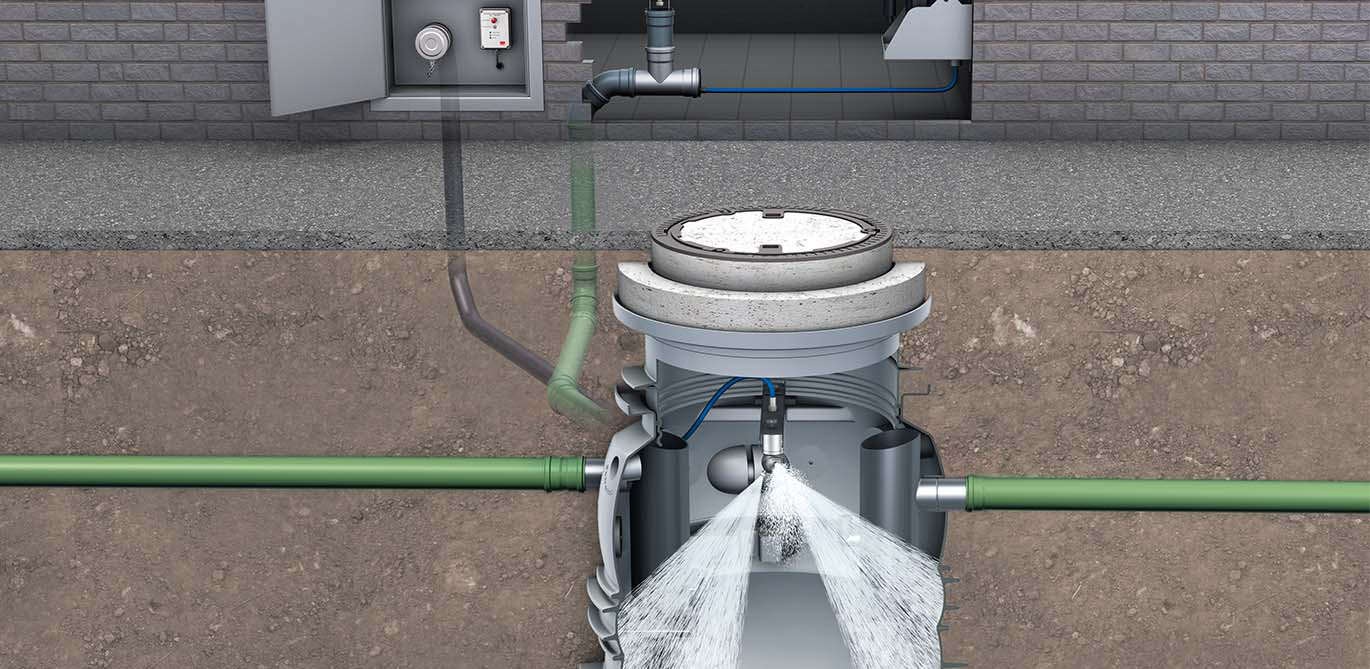

- Connection for direct suction

- High pressure cleaning operated manually

- No odour build-up

Product information

- According to EN 1825

- Inlet and outlet connection according to outside diameter OD depending on nominal size of separator

- Disposal via direct suction line DN 65, PN 10, counter flange and Storz-75 B hose quick coupling and blind cover

- Filling device ¾” with manual operated ball valve to be installed inside a building with cold water supply

- High pressure internal cleaning o high-pressure pump with storag

Product information

- According to EN 1825

- Inlet and outlet connection according to outside diameter OD depending on nominal size of separator

- Disposal via direct suction line DN 65, PN 10, counter flange and Storz-75 B hose quick coupling and blind cover

- Filling device ¾” with solenoid valve to be installed inside a building with cold water supply

- High pressure internal cleaning